Twin coils with SIDAC

IGBT (SISG) supply 2009

This project describes building

two identical Tesla coils and driving them with a solid state driver.

The principles of the SISG driver are described in the two following

topics after this one.

(click to enlarge)

(click to enlarge)

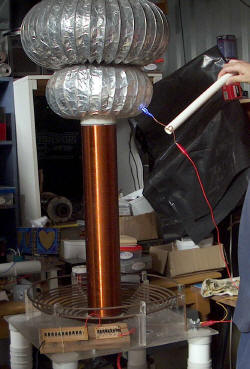

The twin coils firing above with about 80 cm spark from two 50 cm

secondary coils. This is only running on about 60 - 70 % of full

voltage due to a problem with some of the SISG modules.

(click to enlarge)

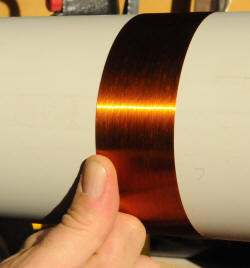

Above shows the winding of the 1260 turns on each secondary using thumb

guidance and a manual winder. Then it gets a couple of coats of

polyurethane (common timber floor sealant). Specs; 1260 turns 26 G 0.40 mm

(.016 inches) over 50.5 cm on 11 cm diam 57.8 cm length 3.5 mm thick PVC

(between 5.0 cm to 57.5 cm.

(click to enlarge)

(click to enlarge)

Above shows the 1/4 inch refrigeration tubing used to make the primary

and the fine polyimide coated high temperature magnet wire for the

secondary. The temporary 8 inch plastic float is coated with aluminum

foil and is assembled with some PVC connection and screws on the end of

the secondary. I am trying to keep this relatively easy to

dismantle for travel and repairs.

(click to enlarge)

(click to enlarge)

The primary coil above is unconventional as I am using a cylindrical

coil rather than a flat helical one. It was wound in minutes, is easily

spaced and tapping is with fuse holders and heavy flexible multi strand

wire. I can tap both ends. Once I get the best results by adjusting the

number of turns, I then go up or down with the same number of turns.

This adjusts the coupling to further optimize the spark length. I must

admit this is a lot more adjustable, faster to wind and more compact

than a helical coil. Most spark gap coils use a helical primary

and most DRSSTC solid state coils use a cylindrical one as they work better

with higher coupling. I am using copper pipe as a coax line to get

the power from the tank caps to minimise losses.

(click to enlarge)

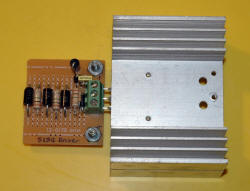

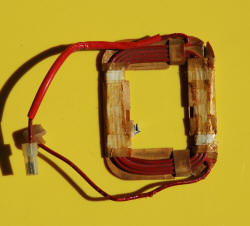

Above shows the SISG driver boards where each 900V section has its own

IGBT with heat sink triggered by 3 x 300 V SIDAC's. Total of 4 boards

with 4 sections giving 14.4 kV firing voltage. The supply is from

two MOT's in a clever voltage multiplier arrangement where the tank cap

doubles as the multipliers caps to generate over 12 kV.

(click to enlarge)

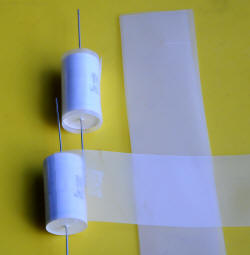

Above shows the 80 capacitors in 8 strings of 10. The capacitors for

this voltage multiplier set up need to be center tapped. As I am not

expecting a significant temperature rise and needed them to be very

compact I individually wrapped 3 layers of polyethylene around each of

the 80 caps so they could be touching and still stand off a maximum of

4kV between them. So far so good. I am only using 60 caps at present. I

am not using resistors across each cap or even across the whole bank as

the voltage in circuit decays in about 5 seconds.

(click to enlarge)

(click to enlarge)

Above shows initial low power runs with a puny 1 cm spark. After tuning

and boosting power the output rose to sparks up to 60 cm from a single

50 cm coil.

(click to enlarge)

(click to enlarge)

Above are the twins in action. Currently giving about 100 cm sparks

between the coils. Still not fully optimized and hope for more.

Sparks are purplish rather than bright white due to the relatively low

capacitance of the spherical topload.

A few references which describe the electronics.

http://drsstc.com/~sisg/SISG.pdf

Terry Fritz's write up of the first single MOT SISG system. This

system generates 30 inch sparks but would be better optimized with a

lower resonant frequency and bigger toroid

http://drsstc.com/~sisg/files/BigSISGCoil/

Lots of SISG related files from Terry Fritz.

http://deanostoybox.com/hot-streamer/temp/PRIANHA-III-too-early.gif

The circuit diagram of the 2 MOT Piranha system.

http://www.teslaboys.com/SISG/SISG4BOM.pdf Parts list for 1 board

http://www.classictesla.com/photos/sisg/sisg.html

Bart Anderson's SISG coil

SIDAC spark substitute solid state Tesla coil. (SSSSSTC)

2005

This is my earliest use of electronics to drive a Tesla coil. It is a proof of principle coil rather than a big performer. It uses

SIDAC's in place of a spark gap (As I use them which is with the tank

cap across the supply rather than the spark gap across the supply).

These are symmetrical breakdown devices.

As set up at present it is driven by a MOT transformer with the

associated 11 kV diode and 0.95 uF 2 KVAC cap wired as a voltage doubler to provide

5.6 KV or so. This is dumped by a SIDAC or

rather 22 in series each shunted by 1 megOhm. Each SIDAC is rated to

breakdown at 240 V and has a 1 A RMS or 20 A pulse capacity. The string of

22 SIDAC's will nominally breakdown at 5280 V. SIDAC's act similarly to a sparkgap.

Data is

here. The

SIDAC's cost US$1.33 each in 10 quantity at

Digikey.

Also shown running ignition coils (with much better performance)

here. This might

have application for small coils running low voltages where spark gaps

become problematic, but without the complexity of an SSTC.

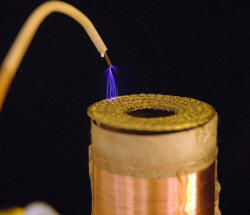

(click to enlarge)

(click to enlarge)

Pic shows 2 inch sparks on my 4 inch coil (5 kV in 60 kV out). I later

used 47 SIDAC's each shunted with 1M

.

I could get small streamers but not much more regular spark length.

However, if I used a spark gap in series with the SIDAC's the spark

length increase was marked and over 6 inches. I interpret this to

indicate that quenching is not really happening with the SIDAC's alone

possibly due to the speed of the devices. I had hoped the SIDAC's

recovery when the current drops would do this but apparently not well or

fast enough. Di/dt is 120A/uS.

.

I could get small streamers but not much more regular spark length.

However, if I used a spark gap in series with the SIDAC's the spark

length increase was marked and over 6 inches. I interpret this to

indicate that quenching is not really happening with the SIDAC's alone

possibly due to the speed of the devices. I had hoped the SIDAC's

recovery when the current drops would do this but apparently not well or

fast enough. Di/dt is 120A/uS.

SIDAC IGBT Spark Gap

(SISG) 2006

SIDAC's are now being used as the triggers for IGBT's to act as a spark

gap with fascinating and evolving information being developed by Terry

Fritz here. Each driver

fires at 900 V to be within the IGBT 1200 V rating. Multiple drivers are

simple daisy chained to reach the desired firing voltage eg 12 kV NST

requires 16 stages which adds to cost. However it does open the way for

using lower voltages in the MOT range where real spark gaps don't work

well. Terry has reached 30 inch sparks with these and Mark has

reached 40 inches. Hot off the

press May 21 2006!

(click to enlarge)

(click to enlarge)

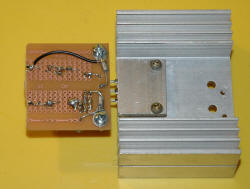

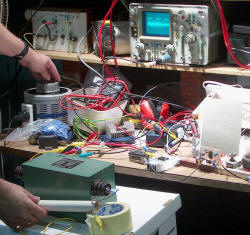

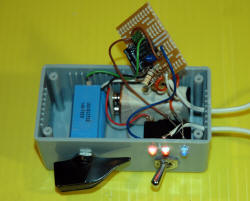

Here is my SISG driver. No I don't have a PCB and yes some of those

components are vertical. I have built it on part of a multikV strip of

SIDAC's that I have cut off.

Nevertheless the fast components have very short paths and should have

low inductance and reasonable current rating. The IGBT fits nicely into

a terminal block to allow changing IGBT's as I want to try some big

IGBT's later. The heatsink was chosen for it's extra holes rather than

need for size. An extra aluminium plate allows the IGBT to be secured.

The black wire allows selection of the number of SIDAC's to use.

(click to enlarge)

(click to enlarge)

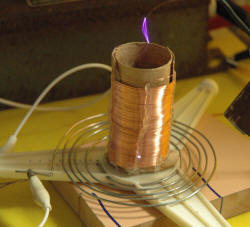

This shows a very rough setup with (almost) 2 turns on the primary and

an SISG running at 900 V with 120 nF resulting in a 1 inch spark.

Vacuum tube Tesla coil (VTTC)

2005

This is a version of a Tesla coil where the primary is driven by a

vacuum tube (valve)

oscillator. I have a Philips TB3/750 power triode rated at 3

kV 1 kW with a 5 V 14 A filament. The high voltage comes from a

microwave oven transformer (MOT) and doubler. The filament supply is from a

rewound microwave oven transformer to give the 5 V. This is largely a

copy of Steve

Ward's VTTC modified to use parts I had on hand.

(click to enlarge)

(click to enlarge)

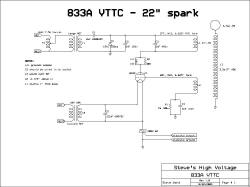

Above left shows Steve Ward's circuit diagram. The 833A

valve is a bit more powerful then the one I have. Above right

shows the parts scrounged from my shed. I haven't had to buy

anything specifically for the coil at this stage. I was donated this and

some other valves by Prof. David Blair (Physics, Uni of Western

Australia).

(click to enlarge)

(click to enlarge)

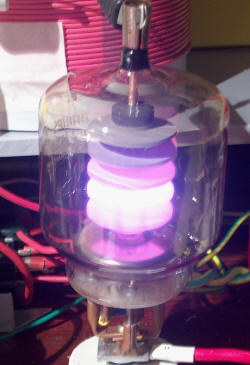

Above left shows the base of the VTTC. Left MOT is for the main HV

with a diode voltage doubler using one of the 3 MO capacitors. Right MOT

is the filament supply. Vacuum tube socket is front centre and MO

suppression filters at rear for each of the two MOT's. Centre photo

shows an early shot in action. This is not in tune and is only

using a single 440 pf tank capacitor instead of the 5 I would need to

get around 2000 pF (= 2 nF). This allows the rather small

secondary coil to run with a relatively large toroid (the only one I

have that looks decent close up). Right photo shows the

tube glowing a bright orange. In this setup it is very

inefficient.

A further step along the way. Still not in tune but with streamers up to

4 inches. Frequency is about 300kHz but with a 2MHz harmonic. I have a

12 inch secondary with about 750 turns of 26g. No staccato yet but I

have the parts.

(click to enlarge)

(click to enlarge)

Photo shows a drinking man's toroid and some sword like streamers.

Vacuum tube is not red (well, for short runs at least).

Liviu Vasiliu has a

database

of VTTC coilers and their sites.

For a really big VTTC I have acquired a

large 60 kW 30 Mhz transmitting triode that runs on 12 kV and has a filament

current of 89 A.

Royer

circuit

2005

Details of this driver driving

flyback and other coils are

here. Here it

is used with a 1+1 turn primary on the base of my 18 inch coil.

click to enlarge

click to enlarge

Solid

state variac

2005 A variac is a variable transformer used to supply

adjustable power for many projects and is invaluable. They are

also expensive as they are large and heavy. Here, I explore the

solid state option which may be preferable in some situations.

This SSVariac I lashed up uses an IGBT out of an inverter microwave run

by a TL494 at 2kHz. The tricky part is that it is "inside" a bridge

rectifier so that it controls AC. This is inserted between the mains and

the NST. There is also a snubber of 0.1uF and 400

that gets pretty hot. I haven't tuned this for long term runs yet as a

lot of power is still being dumped into a 230V MOV across the IGBT.

(Fortunately I have 300 of these)

that gets pretty hot. I haven't tuned this for long term runs yet as a

lot of power is still being dumped into a 230V MOV across the IGBT.

(Fortunately I have 300 of these)

(click to enlarge)

(click to enlarge)

Pic shown full on running one half of an NST. You should be able to

follow the wiring setup from the photo

Yes I am turning an "old fashioned" variac but just to supply power to

the setup.

Yes I am turning an "old fashioned" variac but just to supply power to

the setup.

I don't really think that it would be more expensive than a variac for

NST use of less than 5A 240V. The main rectifier could be 3A diodes,

and the IGBT/Mosfet could be almost any one with a 500V rating at 10A.

The TL494 circuit could be a 555 in this situation. The snubber may

generate some heat and a mains filter is probably wise. A small 12V

transformer or even old 9V plugpack could supply power. As ususal it

depends how much can be scrounged up.

If this can be made to work reliably and effectively then it may be of

interest to those who use NST's.

Tesla coil made only

out of parts from a single microwave oven 2006

Ok, I reckon that there is not enough ingenuity and resourcefulness

going on in budget coiling these days.

So,

on the 4HV forum, I proposed a prize of $US 50 to be paid by me to

the person who makes a Tesla coil with the longest sparks from a

standard microwave oven.

(click to enlarge)

(click to enlarge)

Above, a standard microwave oven with lid off.

The rules were:

One standard domestic MO (microwave oven) less than 1000W to be obtained

free.

MO must be the transformer type not the inverter type.

Only the parts of one oven to be used. No

other parts to be used apart from solder, hot glue or epoxy in

reasonable amounts (not large amounts to make secondary formers).

This also means no PVC, tape, paper or other extraneous substance.

How you adapt the internal parts is up to you.

Progress, results and sparks must all be photographed to confirm use of

only parts of one MO are used. Spark length measured from the photo with

a ruler adjacent.

And the result? Well no one won it. I didn't get the time to

complete mine before the deadline. However I have done it - just 9 days

late. Shown here with 1/2 inch sparks only but best in development has

been 1 inch and plenty of scope for improvement with better design.

Here's how:

Power supply is the MOT. This needs

current limiting and this is achieved with a 150nF capacitor and the

voltage is boosted by a one stage multiplier using the MOT diode to give

4kV peak. Note that power is taken off across the diode not across the

cap to get the voltage multiplier effect. Hey what's this about a 150nF

cap? Where is that in a microwave oven? Well that is the key to this

project. The 1uF 10kV DC mylar and oil cap (that is in all non-inverter

MO's) needs to be taken apart and unwound. Lengths of the multilayered

dielectric and foil are taken out and cut to length. It took about 10

feet of the windings to make 150nF. This is perhaps only 30% of the

total. New electrodes were added.

(click to enlarge)

(click to enlarge)

Above, shows the mylar cap drained of oil and unwound, then rewound with

4 redundant layers for the tank cap.

Tank cap. This is a 1nF cap. The

technique is similar but I retained the original electrodes from the cap

to use in this section as they were better suited to a high current.

Construction of this cap was different in view of the much higher

voltage/current and frequency stresses. It used about 30% of the length

of the cap windings. The plates were only about 1 foot long by 2 inches,

however I used two sections of foil/dielectric between them. The foil

was not connected and was kept to equalise voltage stresses. All in all

something like 12 layers of mylar and 2 foil layers separate the main

electrodes.

Being mylar they do warm up a bit.

Spark gap This is two aluminium

electrodes (from the frame of the MO fan) bolted to part of the MO timer

circuit board with all the components and printed circuit ground off. It

really needs another section to give better quenching.

Primary is the MO transformer 6V winding

which is heavy copper. This is stuck on to the 3 legged wheeled frame

that the glass food tray sits on and rotates.

(click to enlarge)

(click to enlarge)

Secondary former is the cardboard

internal cardboard insulation from the HV cap. It was washed but became

a bit soft but still usable.

(click to enlarge)

(click to enlarge)

Above shows the primary former being HV tested for conductivity.

Secondary windings use wire from the fan

motor and less than half was used. The hot glue didn't stick the

cardboard former together properly and the windings slipped and

overlapped. I have had some interturn shorting (and may still have) so I

can't really push the power much without a rewind. No idea how many

turns.

Toroid I did try winding lots of turns of wire on the fan blades but it

didn't improve the performance. so I just left the metal mesh spacer

that sits on the output of the magnetron for a nice colour.

(click to enlarge)

(click to enlarge)

Photo above shows a spark with inter-turn shorting and also a racing

spark suggesting over-coupling.

(click to enlarge)

Left photo above shows the full setup with the MO transformer

feeding into a voltage doubler formed by the 150 nF cap and diode.

The output is taken across the diode to get the voltage doubler effect.

This means the diode is across the spark gap which does look unusual but

it should give 4 kV peak to fire the spark gap. The tank cap is 1

nF. The center photo shows sparks of up to 1 inch from it

from a 4 kV NST and a 2 gap static gap. The right photo shows the

completed coil running from the MOT. Not fabulous performance but the

proof of principle is there are plenty of opportunities to do better. I

was reluctant to retune and push harder as the 150 nF cap kept blowing

and having to be rewound with a section cut out. The secondary is

overlapping and may not tolerate a higher voltage although I suspect it

may have a properly shorted turn already which is why performance has

dropped despite the power increase.

(click to enlarge)

(click to enlarge)

And finally put back in a MO with the electronics still functional so

you push START and STOP to run it!

Hand-cranked TC 2007

This was just a quickie to demonstrate that one can get sparks with a

hand cranked generator.

I used an antique telephone alternator and was able to demonstrate

sparks about 1/4 inch when cranking out about 100V AC peak into an NST.

Mains is about 375 V AC peak by comparison. I used only one rather than

4 segments of the static gap but other wise my

mini-TC was unchanged.

(click to enlarge)

(click to enlarge)

Above shows a tiny spark in series with a neon on top of my mini coil.

My right hand is a blur of rotation and my left hand is holding the

camera infrared remote (which the camera can see). The out of

focus CRO is set for 50V per division ie just over 100 V peak in a

rather odd shaped wave.

Neon

and Fluoro tubes 2007

This was just another quick demo of a comparison between neon and fluoro

tubes for Tesla coils.

(click to enlarge)

(click to enlarge)

Above shows a similar length neon and a fluoro tube with ends connected.

The electrode end has been made identical by using same sized

electrodes. One has to bring the neon much closer to fire it. Of course

the color is much nicer...

Tesla Tuner

2007

This is a handy little circuit developed by Terry Fritz and is used to

tune Tesla coils, both for primary resonance in parallel and secondary

resonance in series. It is a little 555 oscillator that at

resonance will make LEDs light up brightly. The circuit is

here.

(click to enlarge)

(click to enlarge)

Left photo above shows the internals of my version using on hand

parts. I used a 10 turn pot that I had on hand and various "near

enough" parts. The center photo shows it on with the blue

LED being the power and the red LED's being the ones in series with the

output which will be brightest at resonance. The right photo

shows it in action with a frequency meter indicating 256 kHz resonance

of this small coil with large toroid. The tuner (and frequency meter)

goes between the ground end of the TC and ground. In this case the LED's

will be darkest at resonance. For my large TC the resonance was 41

kHz.